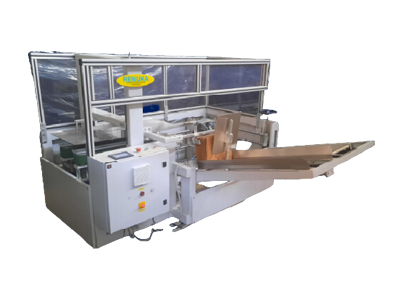

Automatic Carton Erector Manufacturer, Exporter and Suppliers

Automated or partially automated carton/case packaging procedures use carton erectors. The cardboard box is erected (unfolded) and the bottom flaps are sealed, preparing the box for packing. Both fully automatic and semi-automatic carton erectors are available. An operator is needed to manually position the box in the semi-automatic case erector before and after the procedure is complete. However, using a case erector that is totally automatic is a different matter. The totally automatic machine doesn't need to be operated manually. It increases packing efficiency by automatically positioning the cardboard box as it is fed to the erector from a magazine.

A packing device that creates cartons—cartons that are upright, closed, folded, side seamed, and sealed—is known as a cartoning machine or cartoner.

Regarding the Case Round Cases! ses! Not a Jam! The secret to effective ul secondary packaging is square cases. ng. The secret to square re cases is Lantech Case Erectors ors. What Matters in Square Cases Cases that are square protect better, pack better, and stack better. They offer the necessary structural integrity to produce the results that their creator planned. Factual statement: Cases with misaligned sides lose 30% of their stacking strength. How Square Cases Are Made by Lantech Case Erectors A blank is completely under control from the time it enters the magazine until it leaves the case erector as a properly formed and bottom sealed case. Square cases can be built, but obstacles exist. Cases may become "unsquared" or cause machine jams due to thinner corrugated, variations in case blanks, temperature and humidity changes, and changes in the environment. Lantech Case Erectors overcome these barriers through precise case management and 100% control of cases throughout the entire erecting process, ensuring your cases perform as designed and are produced with maximum efficiency. Square cases work better! 90 o Angles on all four sides! A unique pickup frame pulls the case from the magazine and forces it to open so it is square. The flaps are folded before the case moves, making it rigid and locking in its “squareness.” A pusher bar, parallel to the rear wall, delivers it to spring-loaded side belts, which move in or out to compensate for variations in width, and carry it over the sealing device.

Cartoning machines or cartoners are packaging systems which erect, close and fill sealed cartons. In essence, they pick up a flat carton (known as a blank), erect it into a rectangular shape, push the product into the carton (or fill it through a vertical flow), and close the carton via end flaps or a fold-over lid.

Cartooning machines are also known as cartoner is a type of packaging machine that aims in forming cartons. The cartons made from the cartoning machine stands up straight, closed and are folded, side seamed and finally, they are sealed.

Technical Parameter

| Model | AUTO BOXER |

| Production speed | 6 to 10 cartons / min |

| Power supply | 230V, 1Ph, 50Hz |

| Carton size (mm) | L = 200 - 450, W = 150 - 400, H = 100 - 350 * |

| Loading height | 600mm |

| Air compressing | 6 bar |

| Air consumption | 450 NL / min |

| Machine dimension (mm) | L2000 x W2000 x H1500 |

| Machine weight | 450Kg |

| Adhesive tape width | 2” / 2½” / 3” |

Configuration

| MOC | Ms powder Coated Structure |

| Contact Parts | SS304 |

| Linear Bearing | HIWIN |

| Belt | Imported & durable in use |

| Pneumatics | Festo, SMC |

| PLC | Siemens / Fuji |

| HMI | 7” HD Wide, Siemens / Fuji / Pro-face |

| Control Panel | Rittal / Fabricated |

| Sensor | P&F, Leuze |

| Motor | Oriental, Panasonic |

| Guarding | 4040 Al. Profile with 6mm Polycarbonate |